huaihai drying

Focus on the manufacture and service of drying equipment

Searches: dryers, granulators, mixers

huaihai drying

Focus on the manufacture and service of drying equipment

Searches: dryers, granulators, mixers

product description

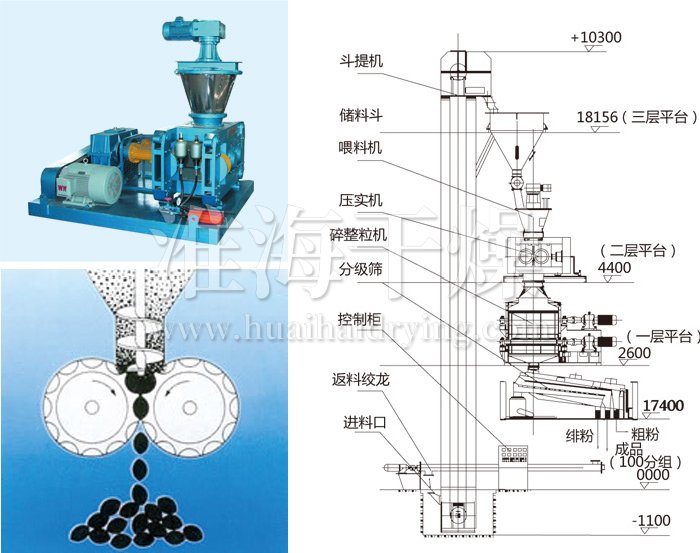

Extrusion granulation is a relatively new process for dry granulation to produce compound fertilizers. Extrusion granulation was applied to the granulation of potassium chloride in the early stage of the fertilizer field, and the granular (1-4 mm) potassium chloride required for blending the fertilizer (BB fertilizer) was basically produced by extrusion. In recent years, extrusion granulation has been developed rapidly in China for the production of compound fertilizers.

The form of extrusion granulation can be two types of roll type and rim type. For roll type extrusion, it is first pressed into large pieces and then broken into particles, so that the device has large capacity, high particle strength and low energy consumption. Roller extrusion is widely used abroad. The rim type is directly formed into a shape of a groove type on the surface of the roll, and is extruded into a molded particle at a time. A lower strength of the product sometimes requires the addition of a binder. Suitable for granular fertilizers such as organic fertilizers and compound fertilizers.

working principle

The principle of the roll extrusion granulation is: the dry material agglomerates into a dense and hard mass (cake material) under pressure, which is called the extrusion process; the cake material is crushed and sieved to become a pellet material. Granular process. The effect of the extrusion is to squeeze out the air between the particles, and to make the particle spacing close enough to produce attractive forces such as van der Waals force, adsorption force, crystal bridge and in-line connection. Extrusion granulated particles are mainly the strength of the particles formed by the forces between the molecules.

Schematic

Technical specifications

| model | Roller center distance | power |

| GZL-240 | 240 | 7.5-1.5 |

| GZL-360 | 360 | 22-45 |

| GZL-460 | 460 | 37-60 |

| GZL-580 | 580 | 45-90 |

| GZL-650 | 650 | 55-200 |

| GZL-730 | 730 | 90-315 |

Contact :Mr.Zhang 0086-18651238882

Telephone:0086-0519-81236002

Fax:0086-0519-81236260

E-mail:huaihaidry@sina.com

Address : Moujia Industrial Park, Zhenglu Town, Changzhou City

Scan it

Scan it