huaihai drying

Focus on the manufacture and service of drying equipment

Searches: dryers, granulators, mixers

huaihai drying

Focus on the manufacture and service of drying equipment

Searches: dryers, granulators, mixers

working principle

After the wet material is put into one end of the dryer, the material is evenly distributed and dispersed in the dryer under the flipping of the inner tube, and the material is fully contacted with the cocurrent (countercurrent) hot air to accelerate the drying heat transfer. Passed to the driving force. In the drying process, under the action of the inclined plate and the hot air flow, the material can be adjusted to the other side of the dryer to discharge the finished product.

Adaptable material

◎ Large particles in chemical, mining, metallurgical and other industries, such as: mine, blast furnace slag, coal, metal powder, phosphate fertilizer, ammonium sulfate.

◎ Drying of powder and granular materials with special requirements, such as: HP foaming agent, distiller's residue, light calcium carbonate, activated clay, magnetic powder, graphite, dregs.

◎Requires low temperature drying and requires large quantities of continuous drying materials.

Performance characteristics

◎The drum dryer has a high degree of mechanization and a large production capacity.

◎The fluid passes through the cylinder with low resistance and low functional consumption.

◎ The adaptability to material properties is relatively strong.

◎ stable operation, low operating cost, and good uniformity of product drying.

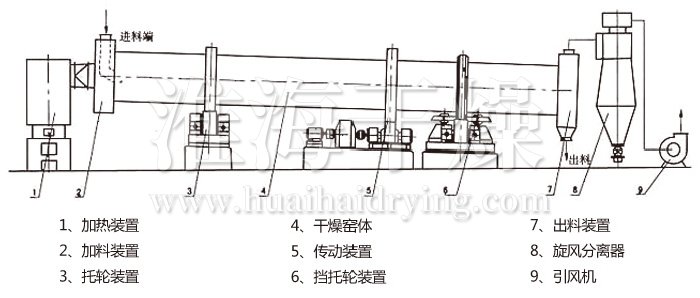

Schematic

Technical specifications

| model | Direct heating downstream | Direct heating downstream | Direct heating counterflow |

Direct heating counterflow |

Compound heating | Compound heating |

| Material type | 矿石 | HPFoaming agent | Blast furnace slag | Ammonium sulfate | Phosphate fertilizer | coal |

| Processing capacity(kg/h) | 1000 | 466 | 15000 | 20000 | 12000 | 5000 |

| Water content(%) | 30 | 13 | 6 | 1.5 | 5 | 6.5 |

| Final water content(%) | 15 | 0.3 | 1 | 0.1 | 0.1 | 0.1 |

| The average particle size(mm) | 6.5 | 0.05 | 4.7 | 0.5-1.7 | 0.5 | 5 |

| Heavy material accumulation(kg/m3) | 770 | 800 | 1890 | 1100 | 1500 | 750 |

| Hot air volume(kg/h) | 3900 | 5400 | 10750 | 9800 | 6500 | 16000 |

| Inlet gas temperature(oC) | 600 | 165 | 500 | 180 | 650 | 570 |

| Material outlet temperature(oC) | 42 | 100 | 70 | 80 | 75 | |

| heating method | gas | Steam electric heating | heavy oil | Coal-fired hot blast stove | heavy oil |

heavy oil |

| Loading factor | 6.3 | 7 | 7.5 | 7.8 | 18 | |

| Rotating speed(rpm) | 4 | 4 | 3.5 | 3 | 4 | 2 |

| Slope | 0.04 | 0.005 | 0.03 | 0.05 | 0.05 | 0.043 |

| Number of copy boards | 12 | 24 | 12 | 22 |

Inner tube outside 8 Outside the inner tube 16 |

6 12 |

| Dryer diameter(m) | 2.0 | 1.5 | 2 | 2.3 |

Outer tube 2 Inner cylinder 0.84 |

Outer tube 2.4 Inner cylinder 0.95 |

| Dryer length(m) | 20 | 12 | 17 | 15 | 10 | 16 |

| Driving power(kw) | 22 | 7.5 | 15 | 11 | 11 | 15 |

Contact :Mr.Zhang 0086-18651238882

Telephone:0086-0519-81236002

Fax:0086-0519-81236260

E-mail:huaihaidry@sina.com

Address : Moujia Industrial Park, Zhenglu Town, Changzhou City

Scan it

Scan it